PCB Design Software Tutorial

PCB is a free software tool for the UNIX operating system that is used

to lay out printed-circuit boards. PCB does not, however, include

a tool for creating circuit schematics. Because the PCBs we will

design have a relatively small number of components, we will forgo the

latter step and just build the layout directly.

To load PCB, at the command prompt type:

/tools1/pcb/bin/pcb

This will bring up the PCB interface. Before starting your

layout, read chapters 1-3 and 8 from the user guide. This will

familiarize you with some of the basic commands and techniques using

the software. The manual can be found at:

/tools1/pcb/share/pcb/pcb.pdf

In addition, an example pcb layout can be found in

/tools1/pcb/share/pcb/tutorial/tut1.pcb

You can use this to experiment with the software before beginning your

own layout.

Designing Your Own PCB

The following tutorial will allow you to become better acquainted with

the PCB software.

1. We will be designing a two-layer PCB only. Therefore,

specify the layers as shown in the figure below. Do this by

selecting Settings -> Edit

layer groupings from the top menu. We will assume that all power

lines will be routed on the top (component side) of the board, while

GND wires and planes will be present on the bottom (solder side).

2. Set the board size by selecting Edit -> Change board size.

Set the PCB width and height to 6000.00 and 3000.00,

respectively. This size should be sufficient for your

board. Note that all measurements are in units of "mils" (0.001

in.).

3. Set the zoom setting in the Screen

menu to 1:2 and select Display grid.

Also change the grid setting to 1 mil.

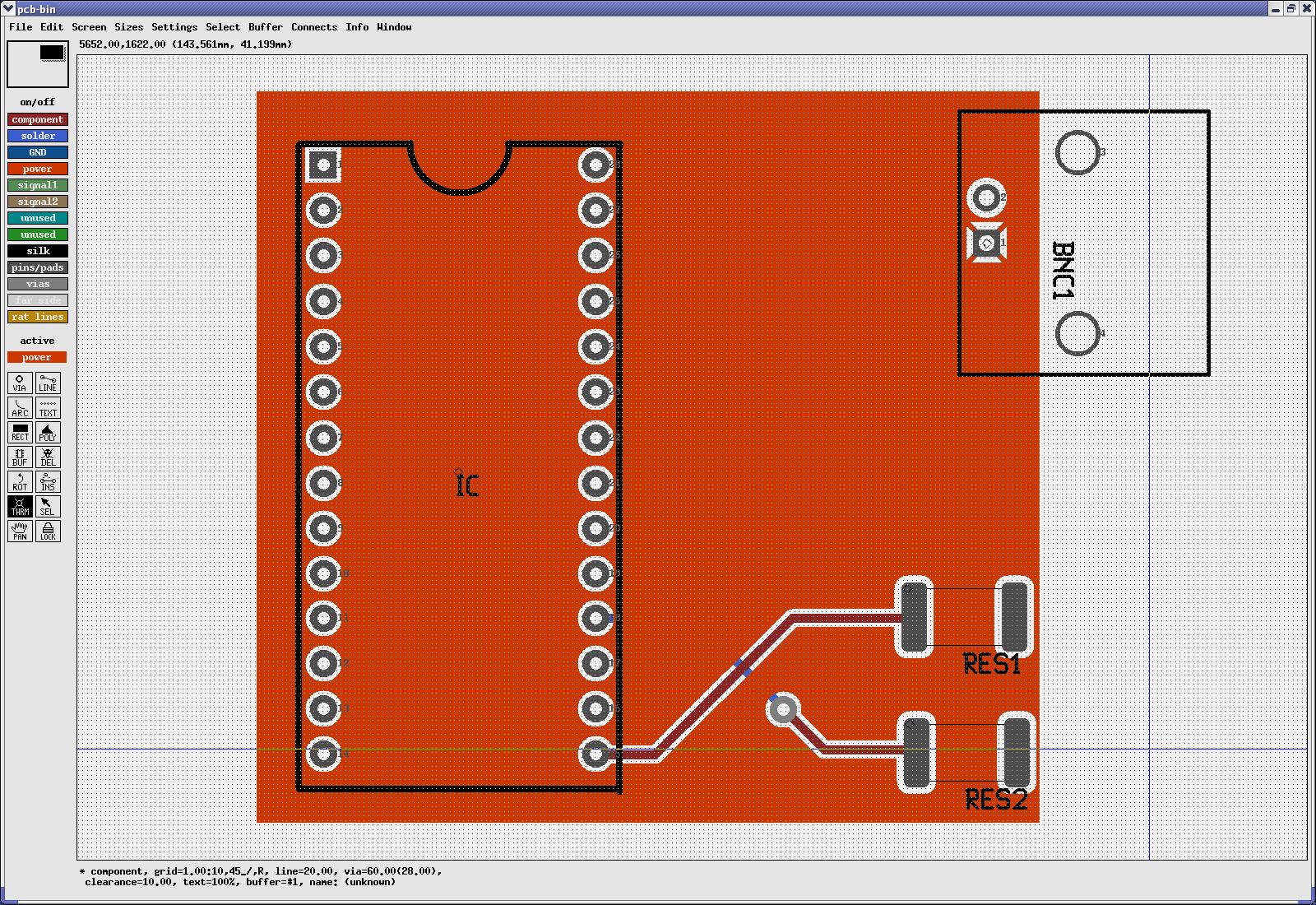

4. We will now place a few component "footprints" on the board

and wire them up. A footprint contains all the pads on which a

real component will sit. We will use BNC connectors to route

power and GND signals. Go to the ~connector group in the PCB

library menu and select the "1, right angle BNC" component. Place

it anywhere in the layout. Now obtain the MOSIS_DIP28_ele component by

accessing File -> Load element

data to paste-buffer and then selecting the directory where this

component resides. Place this near the DIP connector. Note

that these components are known as "through-hole" because their pins

physically pass through the PCB.

5. Go to the ~genericsmt

library and select the "6400, 3200, 750, SMT type capacitor/resistor"

footprint. Place two of these on the board. This footprint

is known as a "surface-mount" component because it contains pins that

sit on the top (or bottom) surface of the PCB. Arrange the

components so that they look similar to the figure shown below.

6. Now we must name each of the components in our layout.

Select the BNC connector, click the right mouse button, and then choose

Edit Name from the list.

Name the connector "BNC1". You will see this name appear on the

footprint. Name the DIP package "IC", and the top and bottom

resistors "RES1" and "RES2", respectively.

7. To view the pin numbers of each component, select the

component and hit "<Esc>D". You may have to zoom in to see

these better.

8. Before we begin drawing the wires, select Sizes and increase the line width

to 20.00. Then make sure the active layer on the left is set to

"component". Select the LINE tool and then draw a wire from pin

15 of the DIP footprint to the left pad of RES1. Your layout

should look similar to that shown in the figure below.

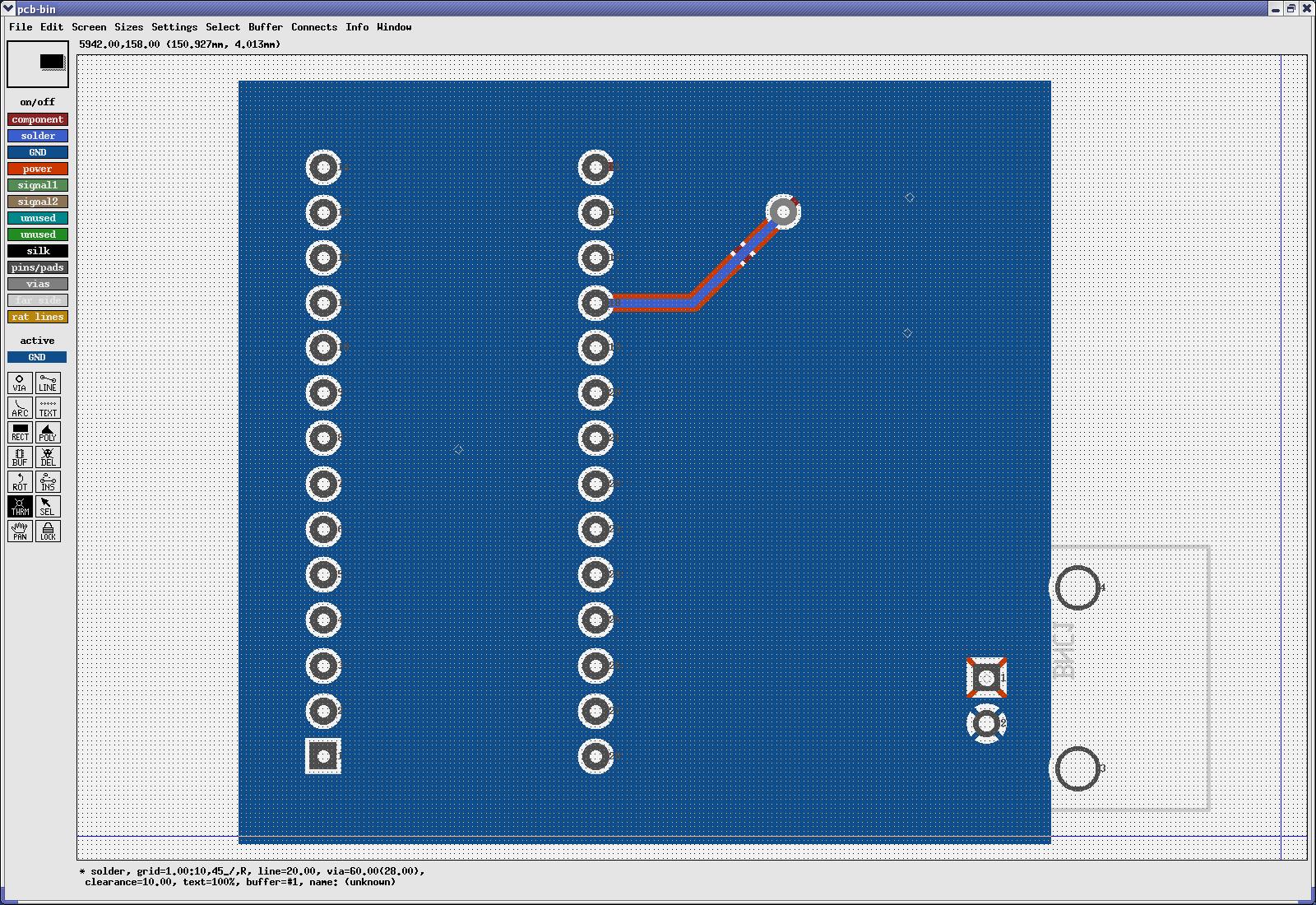

9. Now we will connect a wire from the left pad of resistor RES2

to pin 18 of the DIP. To do this, first drop a via between the

resistor pad and the previously drawn wire. Using the VIA tool on

the left to do this. Then draw a short piece of wire from the

resistor pad to the via using the component layer. Now change the

active layer to solder and

draw another wire from the via to pin 18 of the DIP. Your layout

should look similar to that shown below.

10. Often, power and ground signals are routed using a "plane"

rather than a wire. We will place the power planes on the

component side of the board and the ground plane on the solder

side. To define a power plane, select the RECT tool on the

left and make sure the active layer is set to power. Draw a power

plane that covers the components in the layout as shown below.

Pin 1 of the BNC connector footprint is used to route the power

signal. Therefore, we must connect this to the power plane.

Do this by selecting the THRM (thermal) tool and making sure the active

layer is still set to power.

Press the left mouse button over pin 1 of the BNC connector. Your

layout should now look as shown below.

To define a GND plane, press <TAB> to view the solder side of the

board. Then set the active layer to GND and select the RECT

tool. Draw a plane similar to that shown in the figure

below. Connect pin 2 of the BNC connector to the plane using the

THRM tool as before.

11. When we have finished laying out and connecting all the

components, we must perform a DRC check to ensure that there are no

spacing or width violations. Before doing this, go to Sizes and reduce the DRC minimum

silkwidth to 1.00. Now go to Connects

-> Design Rule Checker to

perform the DRC. The checker will stop and notify you every time

it finds a DRC violation. These errors appear in the program's

log window. Fix any DRC errors before continuing.

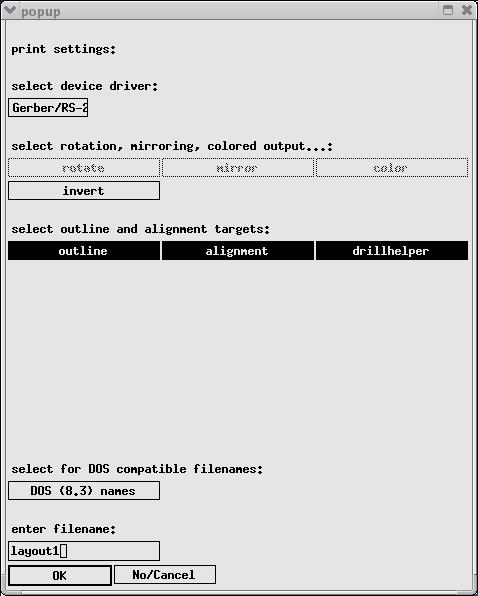

12. The PCB is fabricated by an external manufacturer. The

manufacturer receives a number of text files created by the PCB design

software that contain physical layout data. To generate these

files, go to File ->

Print Layout. Fill in

the form as shown below. In the enter

filename box, type in your directory and the name of your

layout. Hit OK when you

are done.

Additional Information

1. Most of the footprints for components you will need can be

found in the various libraries that come with PCB. If you cannot

find an appropriate footprint, you will need to make your

own. For information on how to do this, see section 8.2 on page

69 of the user's manual.

2. For a list of through-hole and surface-mount components, go to

www.digikey.com and browse through their

catalogues. These usually come with mechanical drawings from

which you can more easily make your own footprints.

3. You can use "rat" lines to logically connect pins from

different components before actually routing wires. This allows

you to optimize the placement and orientation of components without the

inconvenience of moving or deleting PCB traces. The Netlist layer is used for this

purpose. See the user's manual for more information.